Brooke Sasinowski’s 3D-printed Buggies are way cooler than your lame baking-soda volcano.

High-school senior Brooke Sasinowski of Macomb, Michigan, is an aspiring racer who decided to mix her studies with her passion for RC racing. With her ambitions focused on engineering, she re-created her Team Associated RC buggies as computer models, then brought them into the real world via 3D printing. We asked her about the project and her future plans for engineering and RC.

Today, high-school senior. Tomorrow, designing your next RC car.

RC Car Action: What made you decide to 3D-print RC buggies?

Brooke Sasinowski: During my junior year, I saw a miniature RC10 on Facebook. I thought it was adorable, and decided it would be a good idea to base my final project around RC. I created a miniature Team Associated B44.3 in SolidWorks. I then 3D-printed it, all within a week.

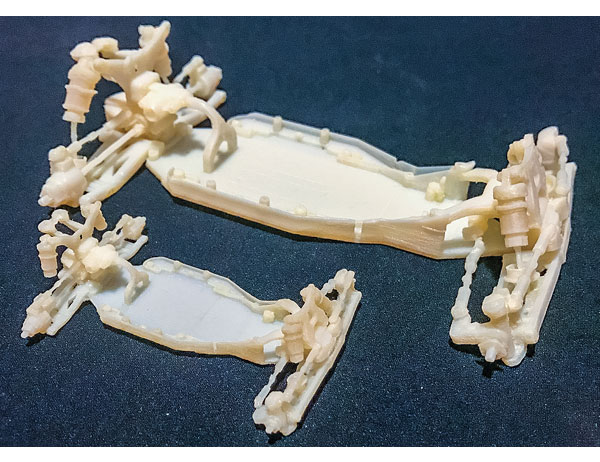

Brooke began with smaller-scale, nonfunctional models—these are approximately 1/20 and 1/30 scale.

RC Car Action: And then you made the 1/10-scale model in your senior year?

Brooke Sasinowski: For my senior year, I based my final project on Team Associated’s clear prototype B6D. I started it in December. After 3D-printing the chassis in PLA [polylactic acid], I decided I wanted to make a second model with a 3D-printed metal chassis. The one with the PLA chassis served as my test car. The metal version was printed with a mix of bronze and stainless steel, and it was my final, functional model.

3D-printed metal? Yep, the chassis is a mix of bronze and stainless steel, says Brooke. Amazing technology.

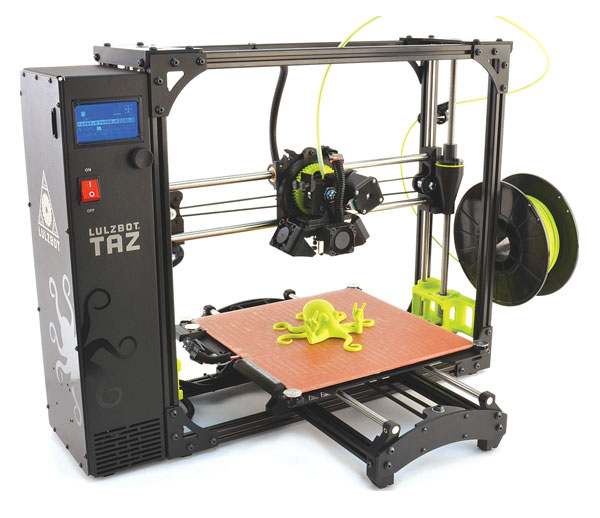

RC Car Action: What design tools and type of 3D printer did you use?

Brooke Sasinowski: I used calipers to measure all the parts and modeled all the parts in SolidWorks Student, provided by my engineering high school. All the parts were printed on the school’s Lulzbot TAZ 6 printer. That was very effective in introducing us to the possibilities available in the 3D printing industry.

3D-printed metal? Yep, the chassis is a mix of bronze and stainless steel, says Brooke. Amazing technology.

Are you planning to find a job eventually in the RC industry as an engineer? It amazes me the amount of engineering that goes into these cars. It would be a dream to be able to work in the RC industry in the future. I plan on going into the RC, automotive, or another technology industry—wherever my engineering path takes me.

Finished, functional chassis. With the exception of the shocks, hardware, and a few other bits, this car is completely 3D-printed.

Keep going—based on this project, we’re sure you’ll do well!

![RC Car Action - RC Cars & Trucks | This 1/3 scale 125cc V10 Buggy is CRAZY [VIDEO]](https://www.rccaraction.com/wp-content/uploads/2018/05/V10-HP.jpg)

Stay up to date with the latest information, sign up for our FREE newsletter today.

Stay up to date with the latest information, sign up for our FREE newsletter today.