Unless you have a drag car, your RC machine has a differential—maybe even two or three. Even though nearly every car has at least one, and differentials are critical to a car’s handling, they are often misunderstood. What does a diff do? How does it work? Which type is best? We have the answers.

What a Diff Does

A differential allows a car’s drive wheels to deliver power simultaneously, even as the wheels are traveling at different speeds while cornering. That’s where the name “differential” comes from: it’s a mechanism that compensates for the differential in wheel speed. But why are the wheels traveling at different speeds? If the car is driving in a straight line, the wheels spin at the same rpm. But when the car turns, the outside wheels must travel farther than the inside wheels, and so the outside wheels must rotate faster (and the inside wheels, slower). So how does the diff “know” what to do? It doesn’t; it’s just a simple mechanical device. Because of its ingenious design, any acceleration of one wheel decelerates the other by an equal amount (and vice versa), so the average rpm of the wheels will always equal the rpm of the differential. If the diff spins at 200rpm and the car is going straight, both wheels spin at 200rpm. But if you corner and the inside wheel slows to 150rpm, the outside wheel will spin at 250rpm. If it slows to 100rpm, the outside wheel will spin at 300rpm. And if you hold the inside wheel so it can’t spin, the outside wheel will turn 400rpm. No matter how you slice it, the average speed of the two wheels will match the rpm of the diff. Pretty neat.

Anytime a car is cornering, the outside wheels must rotate faster than the inside wheels. A differential allows this to happen while both wheels receive power.

Ball diffs & gear diffs

Differentials can be divided into two types: gear and ball. The essential difference is the means by which the differential’s output gears interface with the spider gears. In the case of a gear differential, the gears are just that: gears. In a ball differential, the spider gears are replaced by balls, and the output gears are replaced by flat rings. Each design has advantages and disadvantages—have a look.

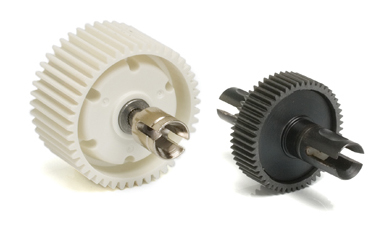

Here’s a typical gear differential from a Tamiya car (left) and a ball differential from Team Associated.

The ball diff (top) uses steel balls that roll on smooth rings to provide diff action without backlash or play while a gear diff must have some play to operate properly.

- Smoothness. A ball diff has the advantage here. Because it has no gears and thus no gear teeth, it has no backlash or free play. This lets the diff transfer power to the wheels very smoothly, even when making very tight turns when there is the greatest speed difference between the right and left wheels. This smoothness helps maintain traction in slippery conditions.

- Durability & maintenance. This is where a gear diff shines. Once assembled, a gear diff can be run with little or no maintenance until it wears out, which can take a looooong time. A ball diff, however, requires periodic disassembly and rebuilding to function at its best (or at all, if you really let it go too long). Gear diffs can also handle more power than ball differentials, which is why you stop seeing ball diffs once you get into high-power/high traction 1⁄10-scale nitro applications and everything 1⁄8 scale and up.

- Adjustability. This one’s a tie, sort of. A ball differential can be adjusted with little or no disassembly; at worst, you have to pop off a camber link and swing a driveshaft out of the way. A ball diff does not have a wide adjustment range, however. If it’s set too loose, it will slip, and that can lead to a diff-gear meltdown. Tightening the diff can slow its action slightly, but even if you sock the diff screw down, it will spin relatively easily. A gear diff is much more adjustable, provided you have the sealed type that can be filled with silicone fluid. By filling the diff with lighter (higher viscosity) or heavier (lower viscosity) fluid, you can set the diff to spin freely or be virtually locked. Unfortunately, you have to remove the diff from the car and open the diff case to change the fluid.

- Weight. Ball diffs win on the scale, and as the heaviest rotating component other than the wheels in most cars, having a lightweight diff is important. The combination of light weight and smoothness is what makes ball differentials so popular for racing in applications where power is low enough that a gear diff is not required.

Unloading—and how to prevent it

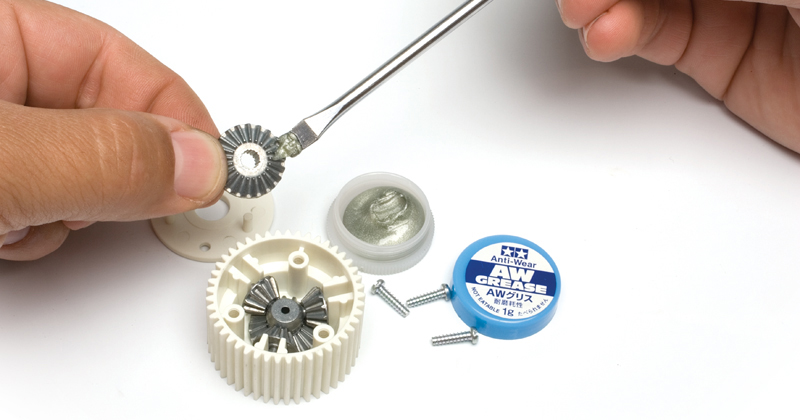

Gear and ball diffs both fall under the heading of “open differential,” which simply means that the diff will happily send power to the wheel with the least traction, or more accurately, to the wheel that requires the least torque. Let’s say your truck is climbing a hill, and one wheel begins to lose traction. The diff will send more power to that wheel, making it spin more, or “unload” into the wheel with the least traction. To compensate for this, racers tried packing thicker grease into their diffs. This does make the diff action feel tighter when operated by hand, but once installed and in use, the diff’s internal gears quickly displace the grease and spin freely again. The solution was the fluid-filled diff, which first appeared with the Kyosho Inferno. By sealing the diff case, racers were able to lube the gears with silicone fluid. Unlike grease, the fluid constantly flows back into the gears, instead of being squished out or flung to the outside of the case and staying put. Diff fluids are also offered in a wide variety of viscosities, from oil-like “thin” fluids to super-thick fluids that seem as though they could be used as bathtub caulk. But what if you don’t have a sealed diff? You can get a similar benefit by using Tamiya Anti-Wear grease in your gear diff. This super-sticky grease clings to the gears and can make diff action very slow. Use just a little at a time to get the diff action you like; if you pack the diff with this stuff, it will lock it nearly solid!

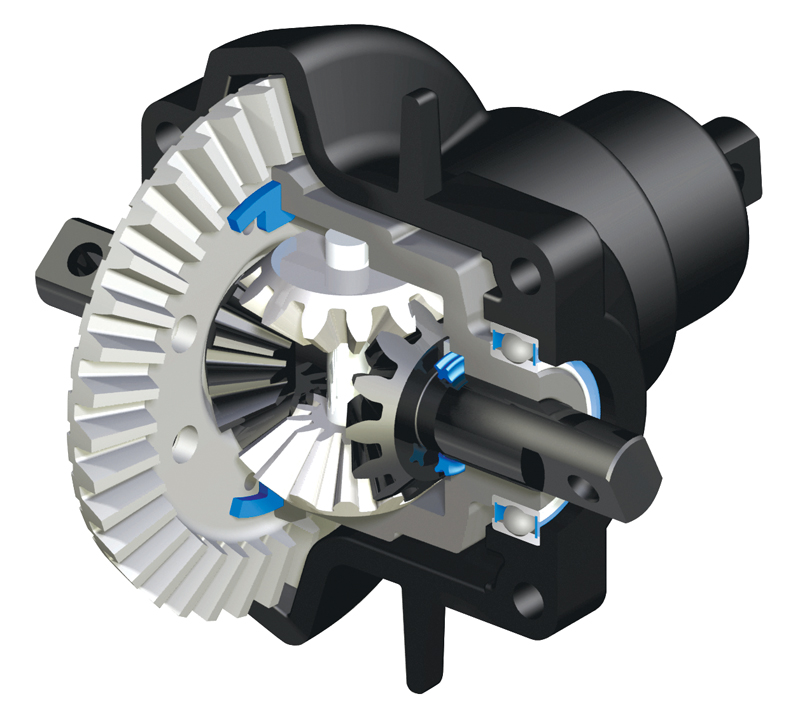

This cutaway of a Traxxas Revo diff shows the seals (in blue) that allow the diff to hold silicone fluid.

Diff fluids are sold in a range of viscosities from easily poured “thin” fluids to sticky goops that barely flow.

Most cars are designed for easy diff access, so fluid changes usually don’t involve too much wrenching. The job can be messy, though.

If your diff isn’t sealed to hold fluid, try using a little Tamiya Anti-Wear grease. The super-sticky grease effectively slows diff action.

![RC Car Action - RC Cars & Trucks | This 1/3 scale 125cc V10 Buggy is CRAZY [VIDEO]](https://www.rccaraction.com/wp-content/uploads/2018/05/V10-HP.jpg)

Stay up to date with the latest information, sign up for our FREE newsletter today.

Stay up to date with the latest information, sign up for our FREE newsletter today.