Think You Have Good Gear Mesh??

How many times have you, or someone you raced/bashed with think they have good gear mesh?? Well in case you didn’t figure out that the “paper trick” doesn’t work alone, you might be surprised there are a few other things to make sure of when setting up your rig with the perfect gear mesh.

This came across my work bench when a friend of mine couldn’t set his gear mesh to save his life. They tried everything, but like some, they had seen “The Paper Trick”. Just run the paper through the gears, snug up the motor and…. Ta da! Your set right??

Sure….if everything else in the gear assembly checks ok.

What do I mean? Let me explain. Here are few things to check over in the life span of your gear mesh on your electric car/truck even if it was perfect at one time. This also applies if the gear mesh progressively got worse, or your just having trouble setting up new gears.

______________________________________________________________________________________

Ok, so we all have been there, and unless you’re a gearing pro and know this method by touch. You will like the paper trick. But there is more to this than meets the eye.

______________________________________________________________________________________

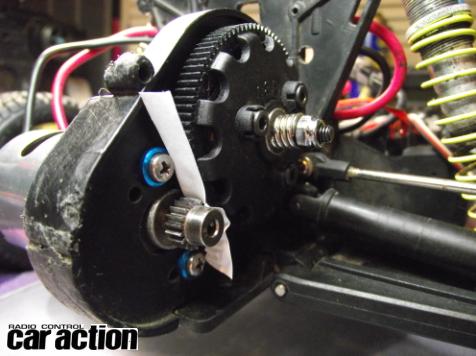

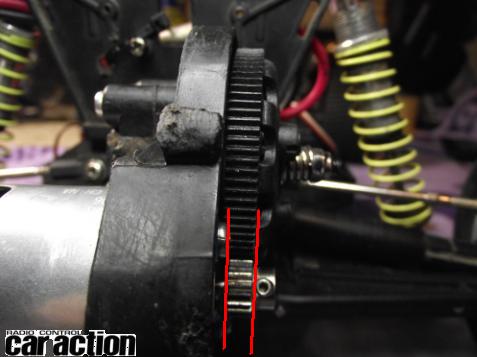

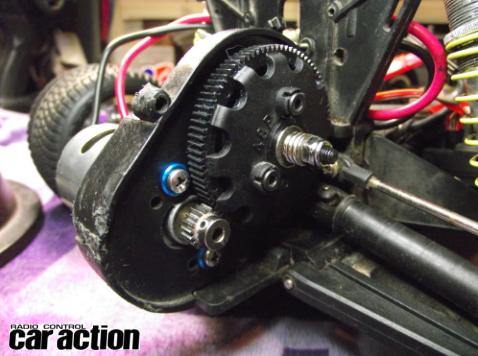

What about the position of the gears? Is this important? You bet it is. While this may rub off as common sense by some, I can tell you I can’t keep count on the cars/trucks of friends and fellow racers that I’ve seen some “interesting” gearing techniques. Make sure the gears are aligned with each other. Picture a straight line from gear to gear along the edge. This makes for full contact of the face of the gear teeth. This will reduce the stress on the gear. Off set gears will allow all the force off to one side on a smaller area of the face of the teeth and will raise the risk of stripping and sheering the gear.

— Note: Make sure the motor is mounted flat and is flush to the motor plate and can still be adjusted with ease. Also make sure the motor screws are good and tight at the end. Nothing sucks more than hitting a jump or getting bumped and the mesh changes because the motor moved.

______________________________________________________________________________________

If after you have made sure the gears are lined up, do a free spin test of the gear assembly. You might want to make sure the spur gear is NOT wobbling in and out from the gear box. This is damaging to the gear and will make it impossible to set a good gear mesh. IF this does occur, remove the gear and check the mounting assembly the gear sits on. Inspect for any kind of debris or metal burs that could cause the one side of the spur gear to dish in and out. (Gear wobble) this applies to this style “Revo Slipper Clutch” and more commonly found “Slipper Ring” type systems.

— Note: make sure to check the input shaft assembly too. This being bent will also cause the gear to wobble and the mesh to get tighter and looser as the gear assembly turns.

______________________________________________________________________________________

You will also want to check the flushness of the spur gear itself. I will admit this trick doesn’t always work but it’s not a bad idea. Find a good flat surface.(setup board works great) Rock the gear back and forth at different spots. If the gear is really bad you will feel a large amount of play from side to side. This gear is probably warped and no longer good. If this happens to a new gear, the mold could be bad. This is common with these types of spur gears. The flatter more common type spur gears can still do the same thing. Take care when removing any spur gear from its bearing/hub assembly. Prying on one side of the gear to pop the gear off can damage the “roundness” of the spur gear.

–Note: check the backside of the gear where the clutch/hub assembly assembles to. Any plastic burs or debris in this spot will also cause a “Gear Wobble”

______________________________________________________________________________________

Ok, so you checked the flushness and alignment of the pinion gear, and spur gear. Everything seems ok, but even when you mesh the gears it’s still pretty noisy.

Before you reassemble everything, check the face of the teeth for damage. Pinion gears come in a variety of material. -Steel, -Aluminum, -Plastic (Yes…plastic) and Brass.

I know steel gears are more common, but like all metals they all have different “hardness” to them. Not all gear systems are covered (but should be) Getting rocks and sand stuck in between the teeth can cause the teeth to chip, pit and even crater.

–Note: if you find a pinion gear (or spur gear) like this, it’s garbage. Don’t bother trying to save it. Throw it out and buy a new one. Pairing this gear up with a new spur gear will only wear the crap out of the new spur gear. You will be back to squire one.

______________________________________________________________________________________

Once the face of the teeth are checked, turn the pinion gear to it’s side and check the side of the teeth. I know it’s hard to see here, but this gears teeth have “curled” and looks almost like a saw blade. Imagine what this did to a spur gear. Perfect gear mesh didn’t stand a chance.

–Note: Results like this are found due to a variety of conditions. This pinion is made from aluminum. While light weight, it’s softer than steel. A larger than acceptable load on the gear teeth will cause this. High torque motors, spur gear slipper too tight or high power brushless systems and even improper gear ratios. Be cautious with light weight aluminum pinion gears.

______________________________________________________________________________________

The same rule applies with the spur gear. Check for pits, chips bent teeth etc. Like the one shown above, the teeth are clean and intact. It’s ready to go.

Bottom line.

With the above tech. notes and the famous “Paper Trick” you should be able to set perfect gear mesh every time. Why is all of this so important? Well the freer moving and less drag on the gears themselves will put less stress and unnecessary load on the motor. This will improve overall run times and gear life. Another plus with a smoother running gear assembly is the overall speed of the vehicle will also improve. All of these are great benefits to a better running vehicle. I know not all of the steps in this article arn’t very helpful with those of you with “fixed” gearing. IE. Not adjustable. *cough* (Tamiya) BUT the inspection of such gears and over running condition of the gear drive train of any kind still applies.

I hope this helps you out the next time you hit a speed bump on the bench and want to diagnose and repair any kind of gear troubles quickly and easily. Some patents are needed when setting up a good gear mesh. Practice makes perfect. Have fun, help out one another and don’t forget to use blue (temporary)lock-tight when applicable. Those set screws on the pinion gear can get you every time.

(…)

______________________________________________________________________________________

![RC Car Action - RC Cars & Trucks | This 1/3 scale 125cc V10 Buggy is CRAZY [VIDEO]](https://www.rccaraction.com/wp-content/uploads/2018/05/V10-HP.jpg)

Stay up to date with the latest information, sign up for our FREE newsletter today.

Stay up to date with the latest information, sign up for our FREE newsletter today.